Paper Pulp Molding Machine Price Guide

Investing in a paper pulp molding machine can be a wise decision for businesses in various industries. This guide aims to provide valuable insights into the factors influencing the price of paper pulp molding machines, helping you make informed decisions for your business.

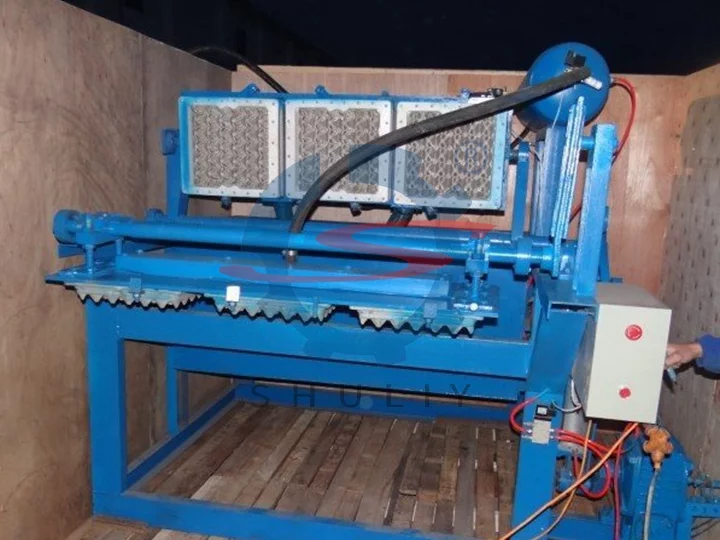

Understanding the Basics of Paper Pulp Molding Machine

The paper pulp molding machine is a specialized equipment used to convert waste paper into various molded products. This section provides an overview of the machine’s functionality, working principles, and its importance in sustainable packaging solutions.

Factors Affecting the Price of Paper Pulp Molding Machine

When considering the purchase of a paper pulp molding machine, it’s essential to understand the factors that influence its price. By considering these factors, you can make a well-informed decision that suits your production requirements and budget.

Machine Capacity: The capacity, measured in units per hour or day, is a significant factor. Machines with higher production capacities generally come at a higher price due to their enhanced productivity and larger size.

Automation Level: Fully automated machines with advanced control systems and robotic operations tend to be more expensive. However, they offer increased efficiency, reduced labor costs, and higher output rates.

Customization Options: Some manufacturers offer customized solutions to meet specific production needs, such as molds for different product shapes or specialized features.

Brand Reputation: Established and reputable brands often charge premium prices for their paper pulp molding machines. Their prices reflect the quality assurance, customer support, and extensive research and development investments associated with their products.

After-Sales Support: The level of after-sales support provided by the manufacturer or supplier can influence the overall price. Companies offering comprehensive customer support, training, spare parts availability, and maintenance services may have slightly higher prices but can ensure a smooth operation of the machine.

Evaluating Cost-Effectiveness and Return on Investment

While the initial investment in a paper tray molding machine is significant, it is essential to evaluate its long-term cost-effectiveness. This section explores factors such as production efficiency, energy consumption, maintenance costs, and the potential for revenue generation. It helps you assess the return on investment and determine the machine’s affordability.

Finding the Right Supplier and Negotiating the Price

Choosing a reliable supplier is crucial when purchasing a paper pulp molding machine. This section guides on selecting reputable manufacturers or suppliers, obtaining price quotations, negotiating terms, and considering after-sales services. These steps ensure a smooth purchasing process and guarantee the best value for your investment.

Investing in a paper pulp molding machine requires careful consideration of various factors, including the machine’s price. Remember to assess your specific requirements and seek expert advice when necessary to ensure a successful purchase.