Paper egg tray production line | apple carton making machine

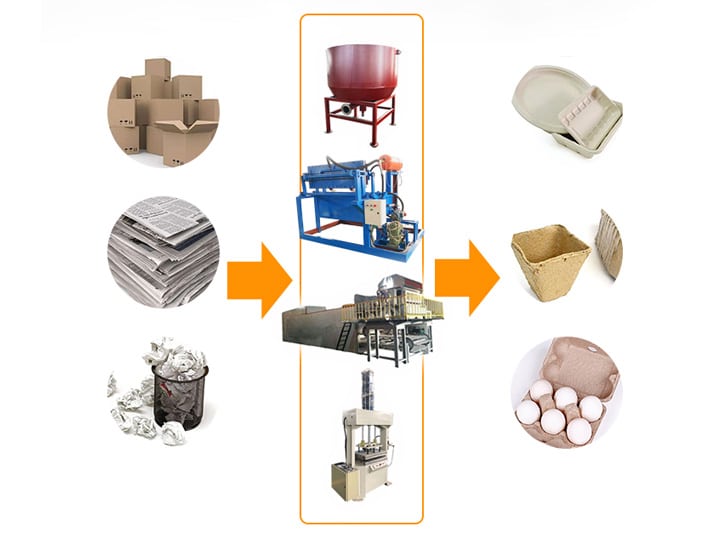

The egg tray production line is a fully automatic production line composed of a variety of machines. Its main machines include pulping machine, egg carton making machine, dryer, egg tray packaging machine. This production line is mainly used for making paper egg tray, the raw material is various waste paper.

How to make egg tray?

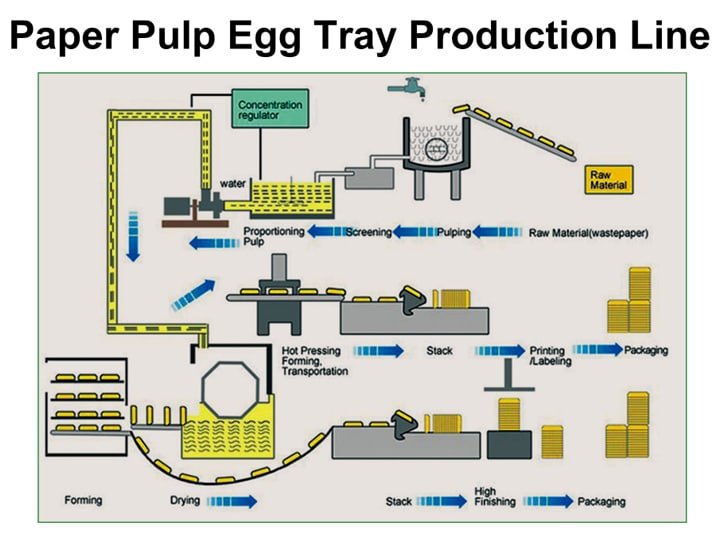

The raw material for making the egg tray is waste paper. When making the egg tray, firstly, a certain amount of water is added to the waste paper to make pulp. The prepared pulp needs to be re-added with water for adjustment. The water in the pool enters the conditioning pool( regulating pool ) through the water pump and is adjusted to a suitable ratio in the pool. The adjusted pulp directly leads to the pulp storage tank at the lower part of the egg tray making machine and can be directly used to make egg cartons. The egg tray forming machine has four different specifications, and the output is used as a standard for dividing different specifications. The egg support machine uses the hot pressing principle to form the egg tray. The prepared egg tray still contains a lot of water, and the egg tray needs to be dried. Due to the different climates, different natural conditions such as sunlight, and the difference in production yield, the drying method can be divided into natural air drying, brick house drying and drying line drying. After the drying is completed, the egg tray is finished.

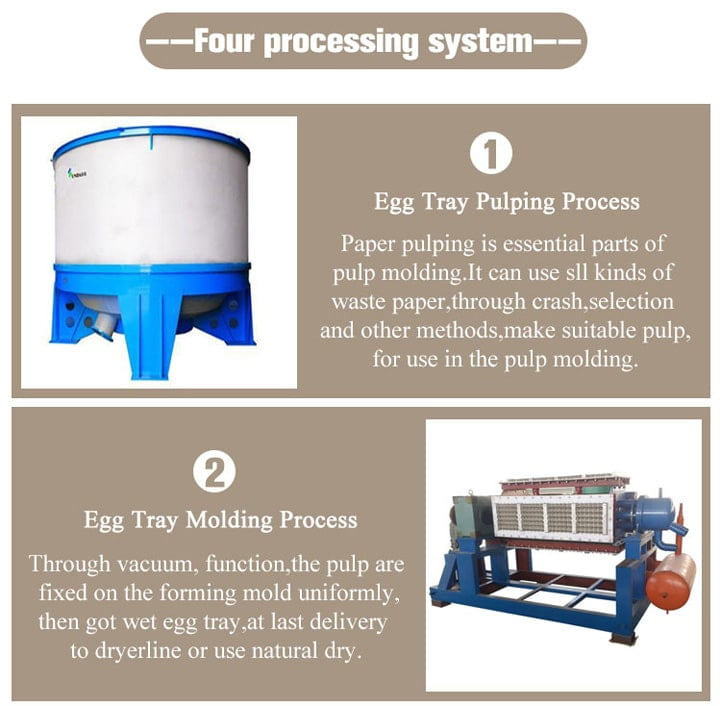

The production process of the egg tray production line:

Waste paper – pulping – adjust the ratio of pulp and water – egg tray forming – drying – the packaging

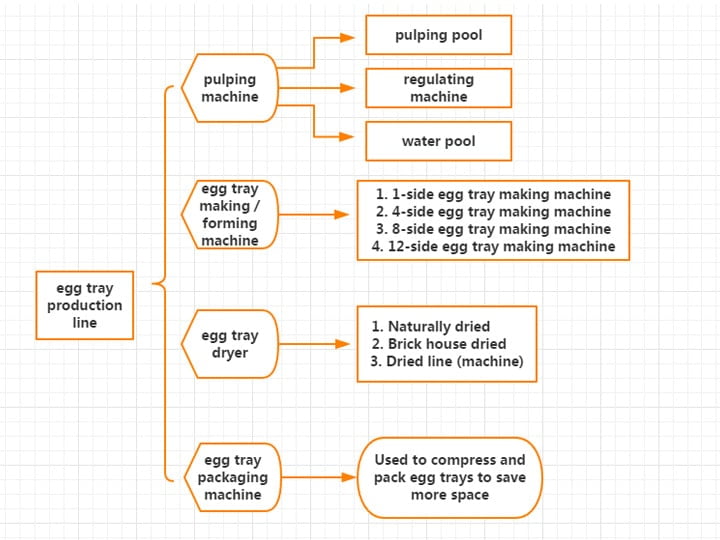

Related machines for the egg tray production line:

Pulping machine – egg tray making machine – dryer – egg tray packaging machine

Video of egg tray making machine:

Egg tray production line application market:

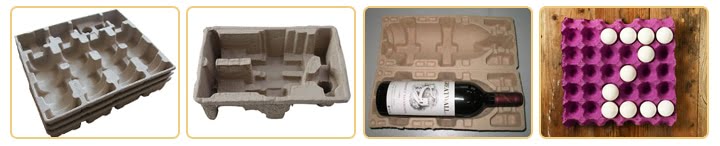

The application market for egg tray machines is very extensive. In fact, egg tray machines can be used not only for making egg trays, but also for making fruit trays, wine trays, electronic components, and small mechanical packaging trays. To make different products, you only need to change the mold, and the mold replacement is very simple and convenient. In addition, since the paper egg tray production line is an environmentally friendly device, its use is more extensive than the plastic egg tray making machine.

An introduction of equipment of the Apple production line:

Step 1: pulp production (pulp machine):

The pulping machine consists of a frame, a pulp bucket, a beater (stirring blade), and a motor. The machine uses the principle of high-speed stirring to break the paper and stir evenly. The internal beater can fully break the waste paper and make pulp in a short time, which saves manpower.

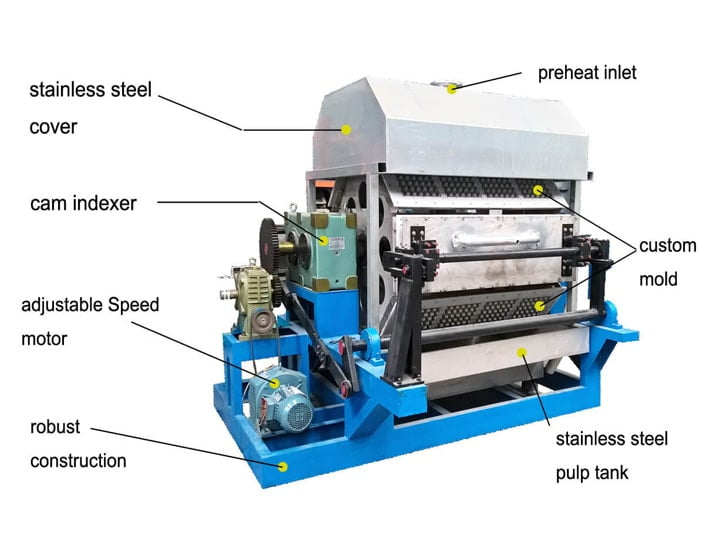

Step 2: Make the egg trays (egg tray forming machine)

According to the different production yields, the egg tray forming machine can be divided into four different models, they are 1-sided egg tray making machine, 4-sided egg tray making machine, 8-sided egg tray making machine and 12-side egg tray making machine. The egg tray forming machine uses the hot pressing principle to quickly extrude the water in the pulp adsorbed on the template and uses the heat to rapidly form the egg tray.

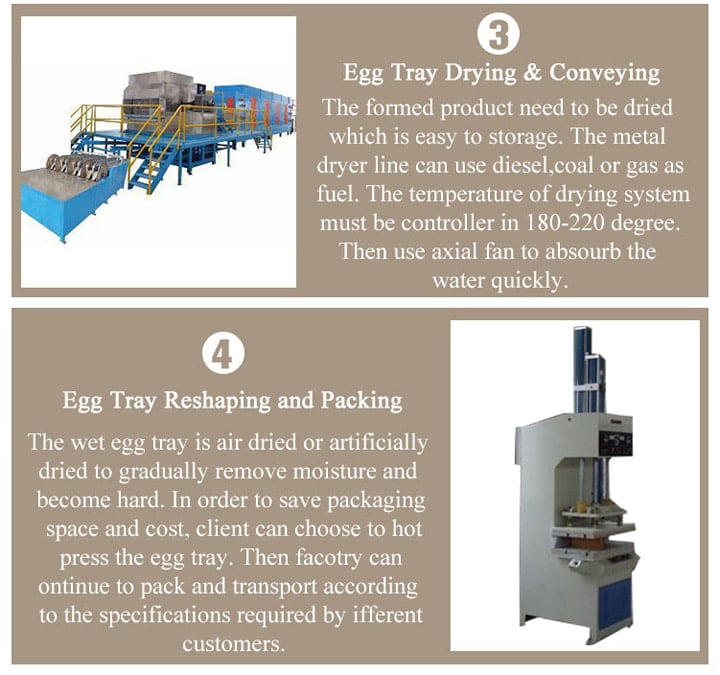

Step 3: drying the egg tray (egg tray dryer)

- Natural air drying: This air drying mode is suitable for countries with abundant sunshine and suitable temperatures, such as Nigeria and India. Also suitable for small production egg tray production lines.

- Brick house drying: First, we should build a brick house for drying, then use coal-fired heating or electric heating to raise the temperature of the brick house to the required temperature, and then use the conveyor belt to transport the prepared egg carrier to the brick house for drying.

- Drying line drying: Drying line drying and brick house are similar in the pattern by building a relatively closed high-temperature space for drying. Both models are suitable for large production, compared with brick drying, drying line drying occupies a smaller plant area.

Step 4: Egg tray packing (Egg tray packing machine)

Egg tray packer is a machine used to pack egg trays. This machine is semi-automatic and needs manual stacking of egg trays. Artificially stacked egg cartons are not compact enough and will occupy more space. The stacked egg trays are placed on the packer, and the pressing plate on the upper part of the machine will compress the egg trays and reduce the gap between the egg cartons, so as to save space.

Features of egg tray production line:

- Molds and other long-term water contact parts are made of stainless steel, and the outside of the machine is coated with waterproof, anti-corrosion paint.

- It can be used to make different kinds of paper trays, such as fruit trays, wine trays, etc. Just replace the molds. It is a multi-purpose machine.

- During the production process, different pigments can be added to adjust the color of the egg tray. (Nigeria customers have asked if we can make purple, green egg trays)

- The prepared egg tray can be molded at one time without causing adhesion and breaking.

- Using advanced German technology and originals, the egg tray is made in a rotating mode, which increases the output and machine life.

What are the advantages of paper egg trays compared to plastic egg trays?

At present, the egg tray commonly used in the market has two kinds of plastic eggs and paper egg trays. Compared with plastic egg trays, paper egg trays have the advantages of good air permeability, waterproof and shockproof, easy to recycle, and low cost.

Machine parameters:

| Model | SL-3*1 | SL-3*4 | SL-4*4 | SL-4*8 | SL-5*8 | SL-5*12 | SL-6*12 | |

| Capacity(pcs) | 1500 | 2500 | 3500 | 4000 | 5000 | 6000 | 8000 | |

| Paper consumption(kg/h) | 120 | 200 | 280 | 320 | 400 | 480 | 640 | |

| Water consumption(kg/h) | 300 | 450 | 560 | 600 | 750 | 900 | 1040 | |

| electricity consumption(kW/h) | 32 | 58 | 78 | 80 | 85 | 90 | 100 | |

| Worker | 3-4 | 4-5 | 4-5 | 5-6 | 3-4 | 3-4 | 3-4 | |

| Single-layer drying tunnel consumables | Coal(kg/h) | 73 | 109 | 150 | 170 | 192 | 218 | |

| Diesel(kg/h) | 28 | 42 | 48 | 60 | 70 | 84 | 115 | |

| Natural gas(m³/h) | 25 | 37 | 51 | 58 | 63 | 75 | 103 | |

| Liquefied gas electricity(kw/h) | 331 | 495 | 563 | 680 | 826 | 990 | 1360 | |

| Workshop floor space(㎡) | 45 | 80 | 100 | 100 | 140 | 180 | 250 | |

| Dryer floor space(㎡) | 216 | 216 | 216 | 238 | 260 | 300 |