Egg Tray Mold

| Brand | Shuliy Machinery |

| Model | Egg Tray Mold Series |

| Capacity | 6 pcs, 12 pcs, 20 pcs, 30 pcs (customizable) |

| Material | Aluminum Alloy / Stainless Steel / Plastic / Composite |

| Size | Customizable according to customer requirements |

| Stacking Style | Single Layer / Stackable |

| Warranty | 12 Months |

| Customization | Supports custom size, material, stacking style, and appearance |

You can now ask our project managers for technical details

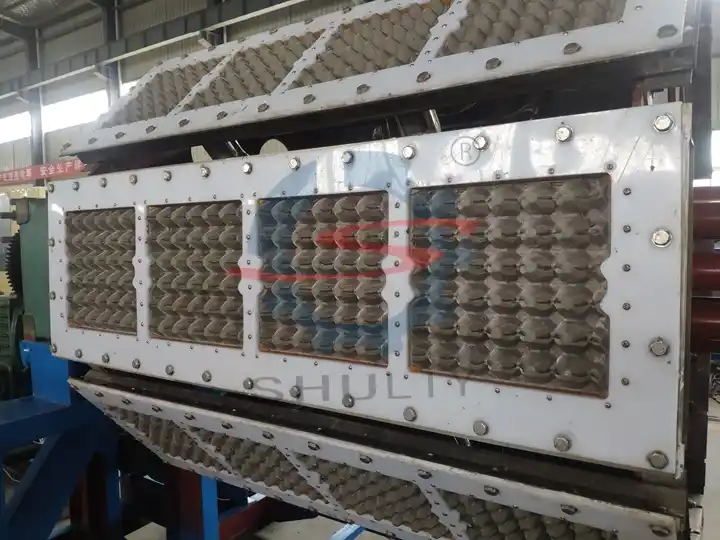

In pulp egg tray production, the egg tray mold is a core piece of equipment in the forming process. It directly affects the tray’s shape, production efficiency, and cost, while its size and design are key concerns for customers.

Shuliy offers egg tray molds in various specifications and sizes, such as 6, 12, 20, and 30 cavities. The cavity diameter and depth can be customized according to egg size. Customers can also choose mold materials, including aluminum alloy, stainless steel, plastic, or combinations of these. Multiple tray styles and surface finishes are available for customization.

Our egg tray molds are durable, corrosion-resistant, and capable of continuous operation in humid environments. They produce uniform, sturdy trays with neat appearances, effectively protecting eggs and enhancing product competitiveness.

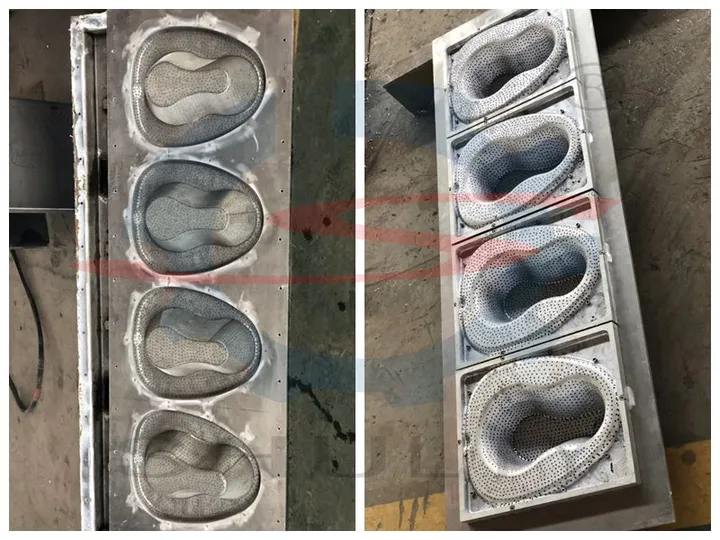

We have designed many egg tray mold for different customer to export to foreign countries. Such as shoe tray, electronic tray, wine tray, fruit tray, egg carton, etc, to foreign countries. Such as a shoe tray, an electronic tray, wine tray, fruit tray, egg carton, etc.

What Materials are Used for Egg Carton Molds?

The most commonly used materials for Shuliy’s egg tray molds are aluminum alloy, stainless steel, and plastic. Other materials can also be customized upon request.

Comparison Table of Three Common Egg Tray Mold Materials

| Comparison Item | Aluminum Alloy Mold | Stainless Steel Mold | Plastic Mold |

|---|---|---|---|

| Market Application | Industry mainstream, most widely used | Special high-requirement conditions | Trial production and small-scale use |

| Initial Cost | Medium | High | Lowest |

| Heat Conduction | Good | Average | Poor |

| Forming Efficiency | High | Medium | Low |

| Forming Accuracy | High | High | Average |

| Corrosion Resistance | Good | Excellent | Medium |

| Wear Resistance | Good | Excellent | Poor |

| Mold Weight | Light | Heavy | Very light |

| Service Life (Reference) | 15 years | 20 years or longer | 2–5 years |

| Maintenance Cost | Low | Relatively low | Low |

Design Features of Egg Tray Molds

Precise dimensions

Accurate control of cavity diameter, depth, and overall tray size ensures consistent products and easy stacking and transport.

Well-designed structure

The cavity shape fits the egg curve, with even wall thickness to ensure strength and reduce material waste.

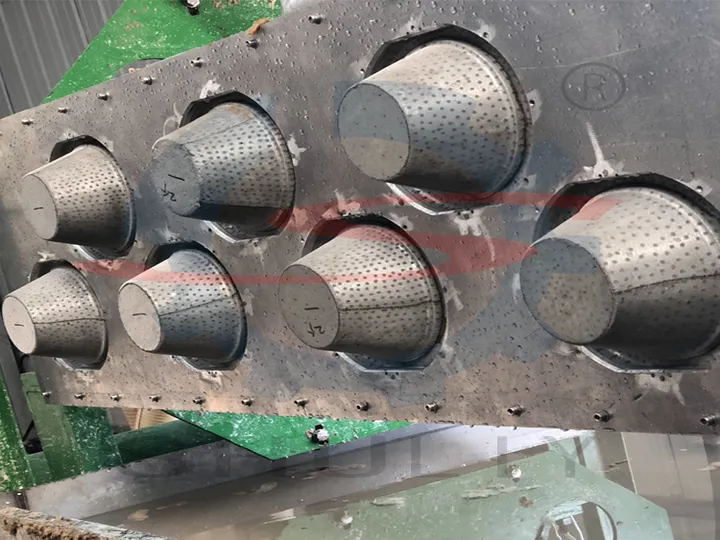

Efficient dewatering and drainage

Proper hole layout allows fast pulp dewatering and improves forming efficiency.

Stable stacking design

Can be designed as single-layer or stackable types to ensure stable stacking without slipping.

Smooth edges and details

Rounded edges reduce burrs and damage, giving trays a neat appearance.

Durability and easy maintenance

Reasonable material and structure design prevents deformation and allows easy cleaning and maintenance.

What Makes a Good Egg Tray Product?

A good egg tray should balance protection, structural stability, and appearance consistency. Key characteristics include:

- Standard dimensions: Uniform cavity size and depth, with consistent overall tray dimensions for easy stacking, packing, and transport.

- Proper strength: Even wall thickness and good load-bearing capacity, reducing breakage during handling and stacking.

- Stable stacking: Well-designed single-layer or stackable structure that prevents slipping or collapse.

- Neat appearance: Smooth edges with no obvious burrs or damage, and clear, well-defined shaping.

- Good shock absorption: Cavities fit the egg shape closely, effectively cushioning external impact and lowering breakage rates.

- Eco-friendly and recyclable: Made from pulp materials that are recyclable and biodegradable, meeting environmental requirements.

How to Customize a Pulp Egg Tray Mold?

Define Egg Tray Specifications

- Number of cavities (e.g., 6, 12, 20, 30).

- Cavity size and overall tray dimensions to ensure compatibility with your production line.

Choose Mold Material

- Aluminum Alloy: Cost-effective with fast heat conduction.

- Stainless Steel: Corrosion-resistant, strong, suitable for high humidity or continuous production.

- Plastic: Low cost, ideal for trial runs or small batches.

- Combination Materials: Stainless steel in key areas and aluminum elsewhere for a balance of durability and cost.

Determine Tray Style

- Stacking type: Stackable or single-layer.

- Frame design: Standard or reinforced.

- Appearance customization: Embossed logo or special patterns.

Provide Production Parameters or Samples

- Forming machine model, capacity requirements, pulp characteristics.

- Samples or CAD drawings to ensure accurate dimensions.

Confirm Design and Proceed with Manufacturing

- Discuss material, dimensions, tolerances, and special requirements with the supplier.

- The supplier provides a 3D rendering or design confirmation before processing.

Mold Testing and Production

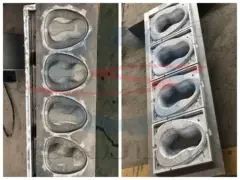

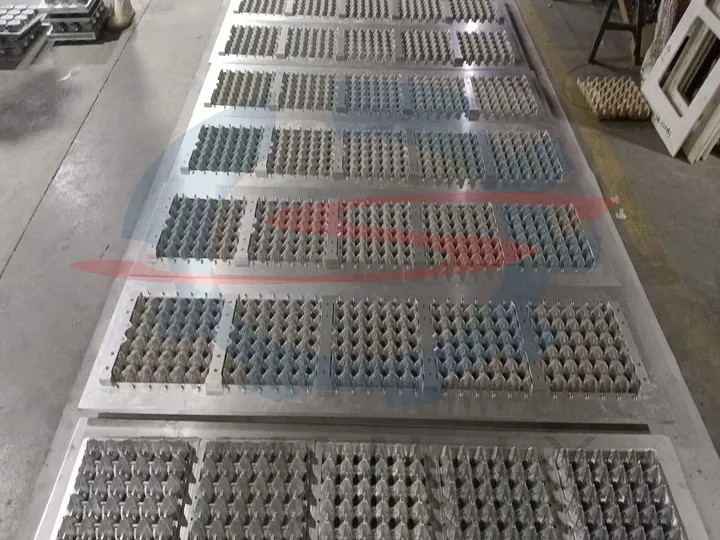

- CNC machining or wire-cutting followed by sample testing.

- Adjust edges, thickness, or drainage holes as needed.

- Once samples pass, the mold is ready for full production.

Application of Egg Carton Molds in Egg Tray Production Lines

Egg tray molds are the core components of an egg tray production line. They shape trays by water absorption or pulp pressing, ensuring consistent cavity and tray dimensions. Molds can be customized in various sizes and stacking structures to improve product quality and production efficiency.

Technical Parameters of Egg Tray Production Lines

| Model | Capacity | Power | Voltage | Weight | Pulp Usage | Water Usage | Size(mm) |

| SL-1000-3X1 | 1000pcs/h | 38kw | 380V,50HZ | 2500kg | 80kg/h | 160kg/h | 2600*2200*1900 |

| SL-1500-4X1 | 1500pcs/h | 38kw | 380V,50HZ | 3000kg | 120kg/h | 240kg/h | 2800*2200*1900 |

| SL-2500-3X4 | 2500pcs/h | 55kw | 380V,50HZ | 4000kg | 200kg/h | 400kg/h | 2900*1800*1800 |

| SL-3000-4X4 | 3000pcs/h | 60kw | 380V,50HZ | 4800kg | 240kg/h | 480kg/h | 3250*1800*1800 |

| SL-4000-4X8 | 4000pcs/h | 95kw | 380V,50HZ | 7000kg | 320kg/h | 640kg/h | 3250*2300*2500 |

| SL-5000-5X8 | 5000pcs/h | 95kw | 380V,50HZ | 8000kg | 400kg/h | 800kg/h | 3700*2300*2500 |

| SL-7000-6X8 | 7000pcs/h | 120kw | 380V,50HZ | 10000kg | 480kg/h | 960kg/h | 3200*2300*2500 |

The above shows the technical parameters of our complete egg tray production line. If you are interested in upgrading your egg tray production line, we welcome you to contact us for consultation.

Customization Capability of Egg Tray Molds

In addition to standard egg trays, Shuliy molds can be customized for various trays such as fruit trays, wine trays, shoe trays, seedling trays, and biodegradable trays. By simply changing the mold, the same production line can quickly switch between products, meeting diverse production needs and enhancing flexibility and versatility.

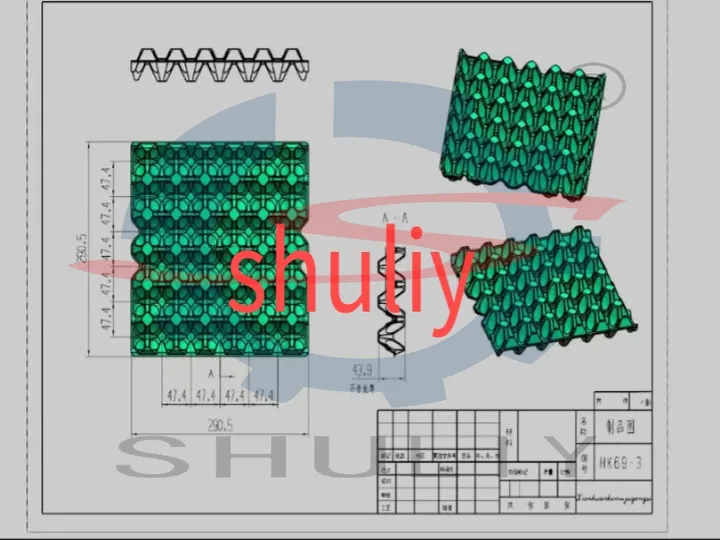

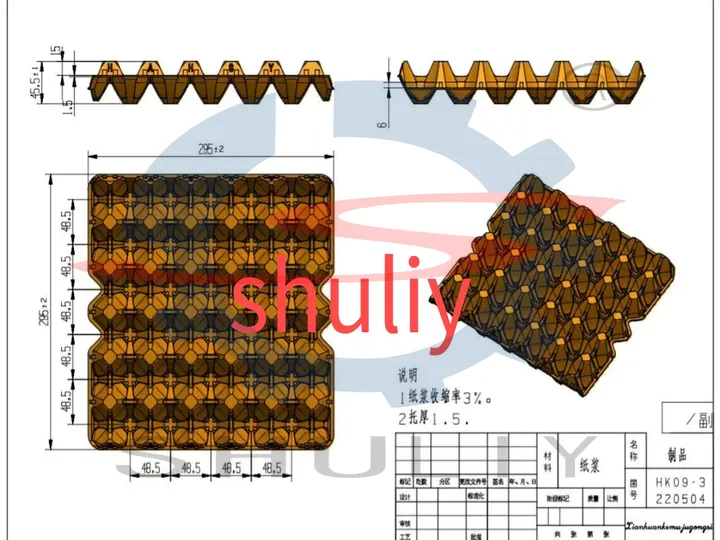

Egg Tray Mold Drawings Display

These are some egg tray mold drawings made for other clients, which you can refer to and review.