Egg tray making machine | paper egg tray Equipment

| Brand | Shuliy Machinery |

| Model | SL Series |

| Capacity | 1000-7000pcs/h |

| Power | 95kw; 120kw |

| Voltage | 380V,50HZ |

| Size | Reference Technical Parameter Table |

| Warranty | 12 Months |

You can now ask our project managers for technical details

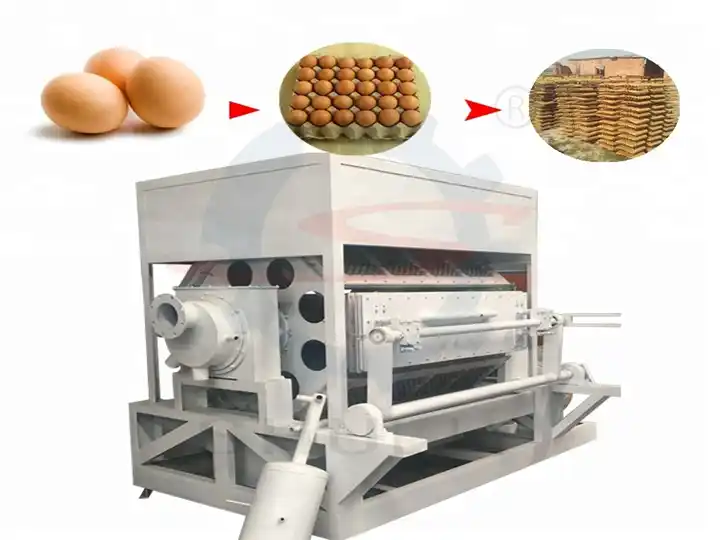

Egg tray making machine is a general name for the pulp egg tray machine, a paper pulp molding machine used to manufacture eggs for long-distance transportation. It mainly consists of machinery such as a forming machine, hydraulic pulper, vacuum dehydrator, air compressor, and drying box. You may need to have a great manufacturing business plan, our professional with rich experience will help you.

Egg trays are widely seen in daily life, available in different shapes and with diverse functions, and can also be used to make egg cartons. With simple production processes, low costs, and eco-friendly characteristics, this industry is regarded as a “green” business.

Shuliy offers seven models of egg tray making machines, including SL-1000-3X1, SL-1500-4X1, SL-2500-3X4, SL-3000-4X4, SL-4000-4X8, SL-5000-5X8, and SL-7000-6X8, with production capacities ranging from 1,000 to 7,000 pcs/h, fully meeting the daily production needs of most enterprises.

In addition, Shuliy provides complete egg tray production lines, from pulping machines to drying systems. Based on your specific requirements, we can also prepare tailored production plans to ensure the fastest return on your egg tray business investment. Each year, we export over 50 egg tray machines worldwide, covering regions such as Africa, Europe, the Middle East, and North America.

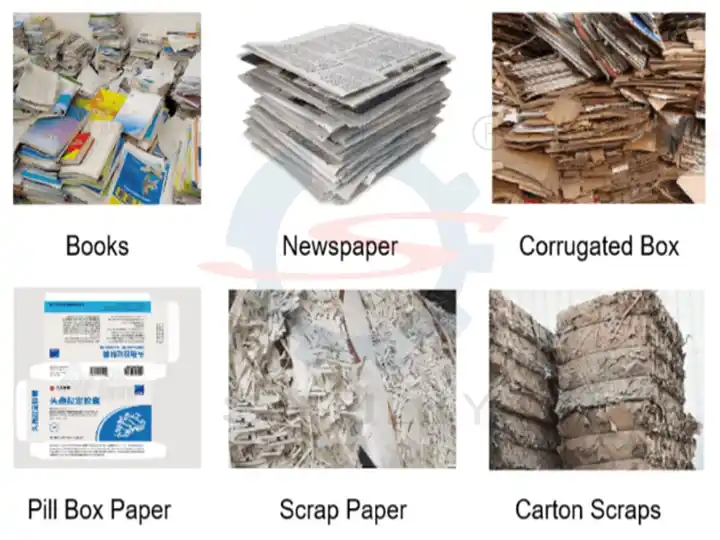

Raw materials for the paper egg tray machine

The whole manufacturing process of the egg tray making machine is very environmentally friendly, starting from the main raw materials used to the egg tray molding. Molded egg trays, molded egg cartons, molded fruit trays, and other tray products are made of waste newspaper, waste carton paper, waste printed matter, and various paper product factory trimmings as raw materials, which are hydrolyzed, filtered, and water injected into a concentrated pulp, which is the raw material for the egg tray machine.

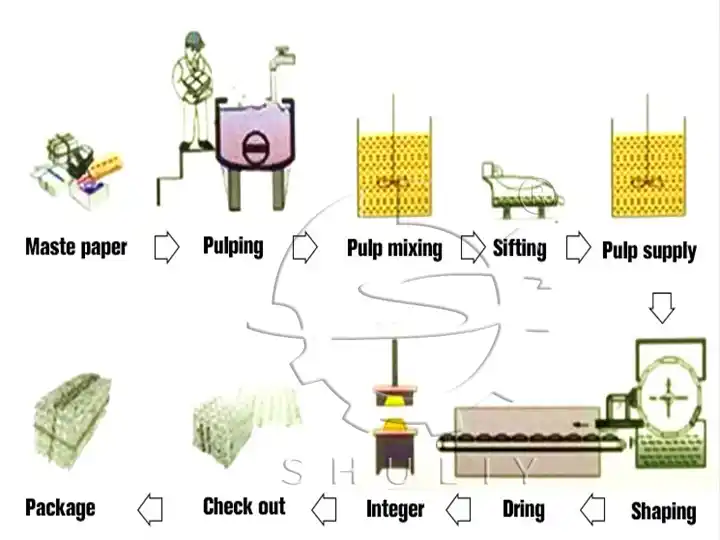

The production process of the egg tray machine

1. Pulping equipment

Paper pulping is an essential part of the egg tray production line. It can process all kinds of waste paper, such as newspapers, waste books, cartons, etc. These waste papers are pulverized and pulped to obtain pulp. The main equipment of the pulping equipment: hydra pulper, vibration screen, consistency controller, thrusher pulp, and control box. It can add a pressure screen refiner and other parts according to the customer’s requirements.

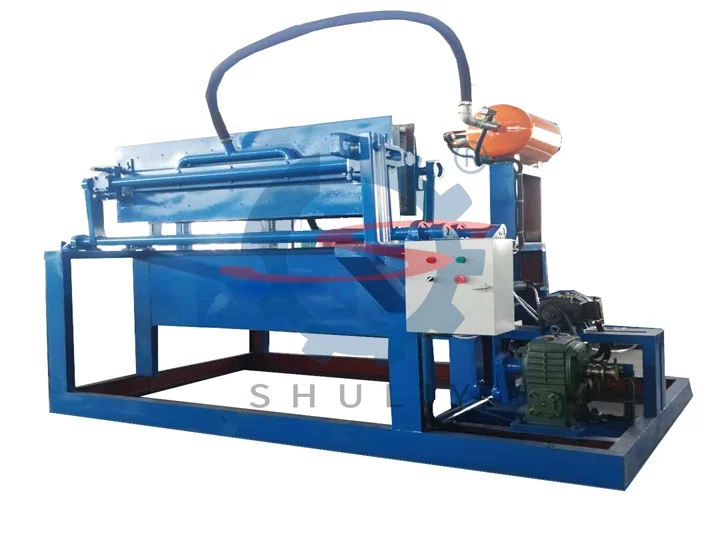

2. Egg tray forming equipment

The egg tray making machine will finish the most important forming step. The pulp is formed on a forming part through the vacuum function. Then we get the wet egg tray. The transfer mold transfers the egg tray to the conveyor belt or small cart, then delivers the egg tray to the dryer line or uses natural drying.

3. Egg tray drying equipment

When the egg tray is forming, it contains a lot of water. So the product needs to be dried, which is easy to store. There are mainly three drying methods: natural drying, brick drying, and a Metal mesh belt dryer. Choose the appropriate drying method according to the capacity. You can choose natural drying if the capacity is below 1500pcs per hour. Metal dryer line: This drying method can use coal, electricity, or gas as fuel.

Then, pulping products can be dried in recycled hot air. The drying temperature can be 180-220 ℃. Then use an axial fan to absorb the water quickly. Our dryer line includes a single belt layer and a multi-belt layer, a single dryer line. The single dryer line length is 42-45 meters. The double-layer length is 22-25 meters. The multi-layer can save the workshop area and use heat more efficiently.

4. Egg tray packing equipment

The pulping mold product through formed and dried, and then can be packed for storage. This egg tray packing machine is used to make the product flatter and smoother. Its temperature is usually 120-200℃.

Parameters of Egg tray making machine

| Model | Capacity | Power | Voltage | Weight | Pulp Usage | Water Usage | Size(mm) |

| SL-1000-3X1 | 1000pcs/h | 38kw | 380V,50HZ | 2500kg | 80kg/h | 160kg/h | 2600*2200*1900 |

| SL-1500-4X1 | 1500pcs/h | 38kw | 380V,50HZ | 3000kg | 120kg/h | 240kg/h | 2800*2200*1900 |

| SL-2500-3X4 | 2500pcs/h | 55kw | 380V,50HZ | 4000kg | 200kg/h | 400kg/h | 2900*1800*1800 |

| SL-3000-4X4 | 3000pcs/h | 60kw | 380V,50HZ | 4800kg | 240kg/h | 480kg/h | 3250*1800*1800 |

| SL-4000-4X8 | 4000pcs/h | 95kw | 380V,50HZ | 7000kg | 320kg/h | 640kg/h | 3250*2300*2500 |

| SL-5000-5X8 | 5000pcs/h | 95kw | 380V,50HZ | 8000kg | 400kg/h | 800kg/h | 3700*2300*2500 |

| SL-7000-6X8 | 7000pcs/h | 120kw | 380V,50HZ | 10000kg | 480kg/h | 960kg/h | 3200*2300*2500 |

The power supply voltage and plug type can be customized. If you would like to learn more, please leave a message in the pop-up window, and I will get in touch with you within 24 hours.

Why choose Shuliy egg tray machine?

- Made of thickened carbon steel, ensuring durability and strong load-bearing capacity

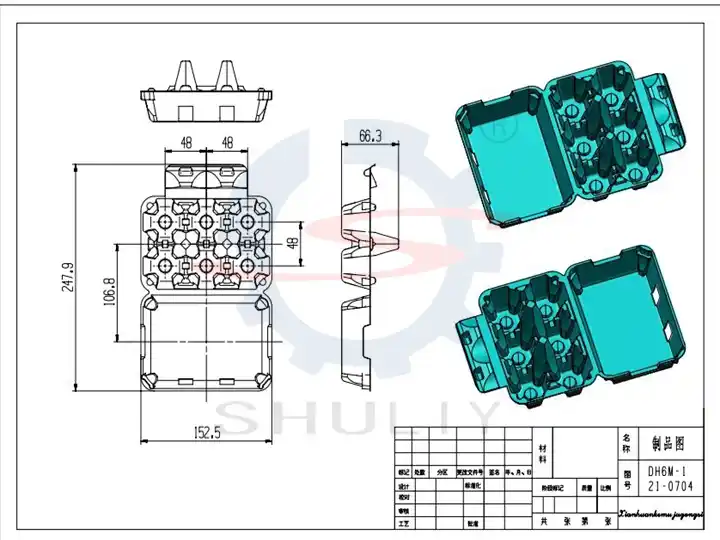

- Aluminum alloy molds (optional stainless steel), lightweight, easy to dry, and convenient to replace

- Non-stick and high-temperature resistant Teflon coating available

- High-strength steel transmission system with wear-resistant bearings

- Stainless steel hydraulic pipes and copper valves for excellent corrosion resistance

- Waterproof and dustproof stainless steel control cabinet

How to judge the quality of egg tray machine products?

The forming quality of the paper egg tray machine is good, poor, or very poor, which is classified by the degree of homogeneity of the egg tray or the uniformity of fiber distribution. It requires that the fiber concentration is the same microscopically in a certain area selected at random on the egg tray.

The closer the fiber distribution is to this ideal state, the more homogeneous it is. Therefore, the quality of the egg tray making machine pulping system is important. The storage of pulp, flow feeding and the performance of the egg tray equipment forming machine all affect the fiber distribution in the paper mold product to some extent.

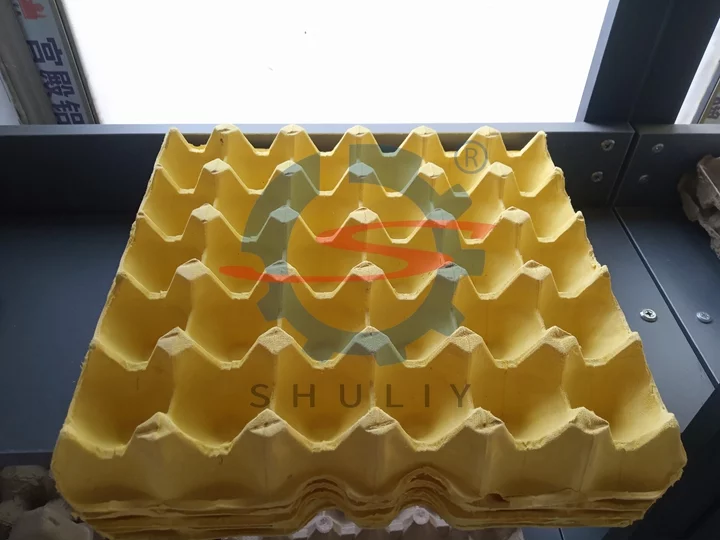

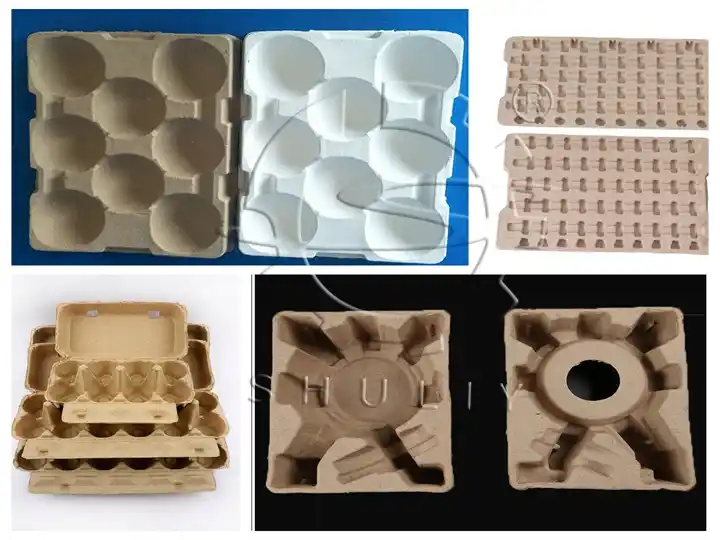

Final products of egg tray making machine

The following paper trays were taken by our sales managers from our factory. The final products of the egg tray machines are not only paper egg trays, but also egg boxes, shoes stand, paper bowls, and so on. It can produce many different shapes according to its molds.

Related egg tray product of egg tray making machine

1. Egg tray

The paper egg tray has better gas permeability, fresh-keeping property, and excellent cushioning and positioning function, especially suitable for large-scale transportation and packaging of eggs, duck eggs, goose eggs, and other eggs.

2. Fruit egg tray

The pulp can be made into a paper tray with a fruit-curved structure for the packaging of peaches, pears, citrus, apples, pineapples, tomatoes, etc., especially for exporting fruit. It can avoid collision damage between fruit.

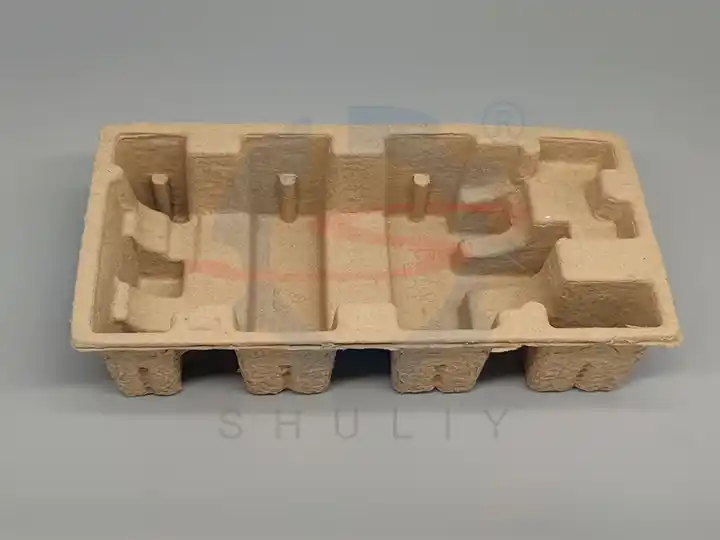

3. Electrical gasket tray

The paper mold material is used as a gasket, which has the advantages of good plasticity and a strong protective effect. It fully meets the internal packaging requirements of electrical products. Its production process will not pollute the environment.

4. Fragile protective gasket

The paper tray is easy to make. It is convenient for packaging and has a shock cushioning capability. Moreover, the raw materials of the products are easy to purchase, the production cost is easy to control, and it is suitable for large-scale production and application.

5. Food (medicine) packaging

Many foods and medicines can be packed in the paper tray. It is not only clean and easy to use but also recyclable, which meets environmental protection and human health requirements.

6. Special industrial paper tray packaging

Some products require great care in packaging, storage, and transportation. They cannot collide, with static electricity, moisture, or rust during transportation. The paper material can solve these problems very well.

Zhengzhou Shuliy Machinery has sold the paper egg tray machine to Nigeria, Morocco, and other countries. The whole production line is easy to learn. The instruction manual is provided with the egg tray making machine. There are semi-automatic production lines or fully automatic production lines. The egg tray making machine price is reasonable in the market. We can produce a shoe tray, fruit tray, apple tray, wine tray, and so on. We will supply a professional sales consultant to solve your problems if you need this machine. Welcome to contact us!

Services Offered by Shuliy

Precision Manufacturing: Crafted with high-precision CNC machines for accurate processing and welding.

Rigorous Quality Control: Every machine undergoes electrical testing, mold inspection, trial runs, and operational checks before shipment.

Expert Installation Support: Our engineers are available for on-site installation, debugging, and trial operation.

Comprehensive Solutions: From pre-sales consultation and 3D design to complete production and delivery, we offer a full one-stop service.

Spare Parts Availability: We provide replacement parts tailored to the specific model you purchased whenever needed.

Reliable After-Sales Service: Delivery managers promptly address operational issues and maintain proactive communication. All machines come with a 1-year warranty.

Win-Win Cooperation with Shuliy

Choosing Shuliy means more than just purchasing a machine—it means partnering with a trusted ally. For 14 years, we have been serving our customers with high-quality products, comprehensive services, and long-term support. We are committed to driving your business forward and working together to build a greener, more sustainable future.