Preis der Produktionslinie für Eierablageformmaschinen

Wenn Sie ein Eierschalen-Unternehmen gründen möchten, finden Sie hier die komplette Produktionslinie für Eierschalen-Formmaschinen. Und der Preis richtet sich nach Ihrer Kapazität, Ihrer Standortbeschaffenheit und mehr. Und wir empfehlen Ihnen die richtige Eierablagemaschine und den richtigen Trockner, um Ihre Investitionskosten zu senken. Außerdem erhalten Sie von uns die besten Angebote. Nehmen Sie jetzt Kontakt mit uns auf.

Eierablage-Formmaschine für Ihr Unternehmen

Unser Eierschalenformmaschine gibt es in verschiedenen Modellen mit Produktionskapazitäten von 1000 Stück pro Stunde bis 8000 Stück pro Stunde. Im Allgemeinen wird bei Produktionskapazitäten unter 3000 Stück pro Stunde der Einsatz einer Eierschalen-Trocknungsmaschine nicht empfohlen.

Stattdessen wird die Lufttrocknungsmethode empfohlen, da die Trocknungskosten relativ hoch sind. Die Einführung einer Trocknungsanlage würde die Kosten erhöhen und bei geringeren Produktionsmengen könnte die Rentabilität eingeschränkt sein.

Bei Produktionskapazitäten über 3000 Stück pro Stunde kann die Gewinnspanne zwar sinken, das höhere Produktionsvolumen gleicht dies jedoch aus. Daher bleibt die Gesamtrentabilität günstig, auch wenn der Gewinn pro Stück leicht sinken kann.

Wie viel kostet eine komplette Produktionslinie für Eierschalen?

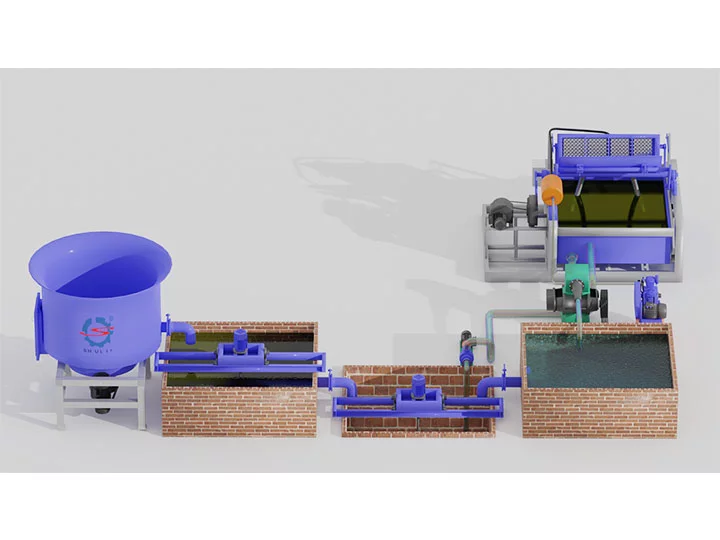

Die Kosten für eine Produktionslinie für Eierschalen variiert je nach den örtlichen Umgebungsbedingungen und der verfügbaren Fabrikfläche. Für den Aufbau einer umfassenden Eierschalen-Produktionslinie sind verschiedene Geräte erforderlich, darunter eine Zellstoffherstellungsmaschine, eine Eierschalen-Formmaschine und ein Eierschalen-Trockner.

Aufgrund der unterschiedlichen Produktionskapazitäten ist der Preis für jedes Gerät unterschiedlich – im Allgemeinen sind Geräte mit höherer Kapazität mit einem höheren Preis verbunden. Darüber hinaus wirkt sich die Wahl der Trocknungsmethode auf die Investitionskosten aus. Für Trocknungsprozesse ist möglicherweise Strom oder Kohle erforderlich, während die Lufttrocknung keinen zusätzlichen Energieaufwand erfordert.

Die klimatischen Bedingungen unterscheiden sich stark von Region zu Region. In einigen Gebieten herrschen hohe Temperaturen und nur minimale Niederschläge, sodass Lufttrocknung eine geeignete Option ist – dies ist in vielen afrikanischen Ländern mit konstant hohen Temperaturen häufig der Fall. Umgekehrt eignen sich Regionen mit häufigen Niederschlägen und hoher Luftfeuchtigkeit weniger für die Lufttrocknung. Für die detaillierten Kosten kontaktieren Sie uns bitte.

Papiermasse-Eierablage-Formlinie-Maschine

Papierzerkleinerer:

Diese Maschine ist für die Zerkleinerung der Rohstoffe in eine Zellstoffmischung verantwortlich, indem sie mit Wasser vermischt wird.

Eierablage-Formmaschine:

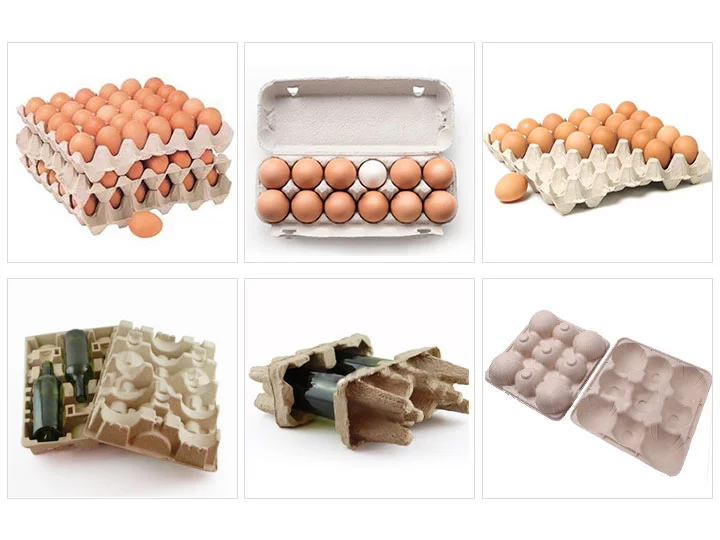

Diese Ausrüstung verwendet die Fruchtfleischmischung, um die Form und das Design der Eierschalen zu formen, wobei normalerweise Formen mit unterschiedlichen Hohlräumen verwendet werden.

Eierschalentrockner:

Die Trocknungsmaschine oder der Ofen wendet Hitze an, um die Feuchtigkeit aus den geformten Eierschalen zu entfernen und sicherzustellen, dass sie stabil und gebrauchsfertig sind.

Verpackungsausrüstung:

Nach dem Trocknen werden die Eierschalen entsprechend den spezifischen Verpackungsanforderungen gehandhabt und verpackt.