Maschine zur Herstellung von Apfelschalen aus Papier | Produktionslinie für Fruchtfleischtabletts

Die Ausrüstung zur industriellen Verarbeitung von Obstpapierschalen ist mittlerweile für viele Investoren ein wichtiges Investitionsprojekt. Unter ihnen ist die Maschine zur Herstellung von Apfelschalen aus Papier eine ideale Maschine für die Verarbeitung von Obstschalen. Das Kommerzielle Apfelschalenverarbeitungsmaschinen können verschiedene Altpapierkartons und Zeitungen recyceln und zu Obstschalen unterschiedlicher Spezifikationen verarbeiten. Darüber hinaus können Größe, Farbe, Gewicht usw. der Apfelschale aus verarbeitetem Papier je nach Kundenwunsch individuell angepasst werden.

Einführung der Maschine zur Herstellung von Apfelschalen aus Papier

Fruchtfleisch-Apfelschalenmaschine Verwendet Altzeitungen, Altkartons, Altdrucksachen und Abfälle aus verschiedenen Papierproduktfabriken als Rohstoffe und wird durch Prozesse wie hydraulische Desintegration, Filtration und Wassereinspritzung in eine bestimmte Schlammkonzentration eingemischt. Die spezielle Metallform wird in einen nassen Rohling vakuumadsorbiert, und der geformte nasse Rohling wird dann getrocknet und heißgepresst, um ihn zu formen.

Apfelschalen, hergestellt in der Obstschalen-Produktionslinie

Obstschalen aus Papierzellstoff

Bestandteile der Produktionslinie für Obstschalen aus Papierzellstoff

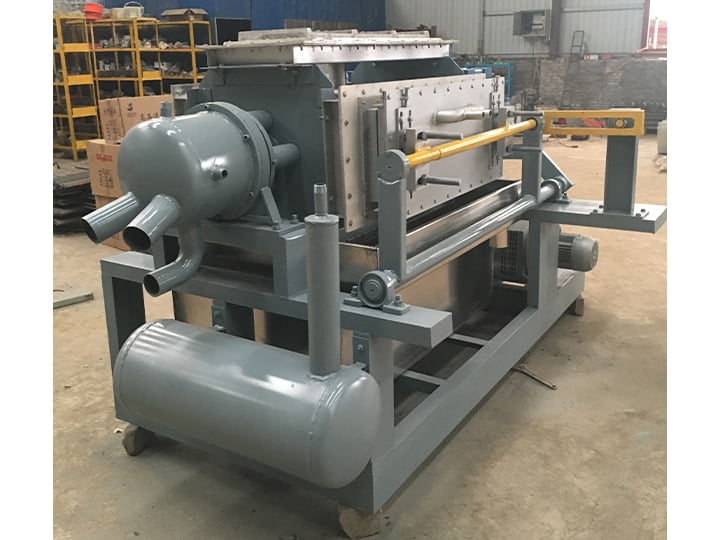

Die Maschine zur Herstellung von Apfelschalen hat eine kompakte Struktur und eine relativ einfache Bedienungsmethode. Für die Verarbeitung von Fruchtfleisch-Apfelschalen ist in der Regel ein kompletter Satz an Verarbeitungsgeräten erforderlich, wie z. B. eine Zellstoffmaschine, ein Fruchtfleischmischer, ein Fruchtfleisch-Lagertank, eine Apfelschalen-Formungsmaschine und ein Apfelschalen-Trockner.

1-Aufschlusssystem: Pulper, Schlammpumpe, Vibrationssieb, Refiner, Rührwerk usw.

2- Formsystem: Trommelformmaschine, Form, Luftkompressor, Luftkompressortank, Vakuumpumpe, Vakuumtank, Hochdruckwasserpumpe, Dampf-Wasser-Trennpumpe usw.

3-Trocknungssystem: Heißluftgebläse, Entfeuchtungsventilator, Entfeuchtungsrohr, Brenner, Brennkammer, Förderband, Kette usw.

4-Verpackungssystem: Pressausrüstung, Verpackungsmaschine usw.

Rohstoffe zur Herstellung von Apfelschalen aus Papier

Die Rohstoffe für die Herstellung von Apfel-Eierschalen aus Papier sind hauptsächlich Altzeitungen, Kartons und Altpapier aus Papierfabriken, Kartonfabriken und Druckereien. Daher sind die bei der Herstellung von Obstschalen verwendeten Rohstoffressourcen reichlich vorhanden, der Preis niedrig und die Produktionskosten niedrig.

Darüber hinaus fallen bei der Herstellung der Apfelschalen weder Abwasser noch Abgase an. Das im Produktionsprozess verwendete Wasser kann recycelt werden, belastet die Umwelt nicht und kann Wasserkosten sparen.

Arten von Apfelschalen aus Papier

Der pMaschine zur Herstellung von Apfelschalen kann verschiedene Formen von Obstschalen verarbeiten. Diese verschiedenen Arten von Obstschalen können zur Aufnahme unterschiedlicher Obst- und Gemüsesorten wie Birnen, Mandarinen, Orangen, Kiwis, Kakis, Tomaten usw. verwendet werden. Darüber hinaus können Größe, Farbe, Dicke und Form der Apfelschale individuell angepasst werden.

Wie macht man Apfelschalen glatter?

Apfelschalen, die von einer Obstschalenbearbeitungsmaschine bearbeitet werden, weisen in der Regel raue Oberflächen auf. Die Apfelschalen, die wir oft sehen, sind normalerweise glatt und haben eine regelmäßige Form. Warum? Dies liegt daran, dass die Papierschale, die direkt von der Fruchtfleischformungsmaschine für Apfelschalen gepresst wird, weiter erhitzt und extrudiert werden muss. Wir können die Apfelschale mit einer Heißpresse weiterverarbeiten.