Investment Cost Analysis for Egg Tray Manufacturers

Understanding the investment costs is crucial for egg tray manufacturers. Starting with the machinery in the egg tray production line, we offer the main investments needed, followed by a detailed cost analysis. This comprehensive approach ensures a well-informed decision-making process for your egg tray manufacturing plant.

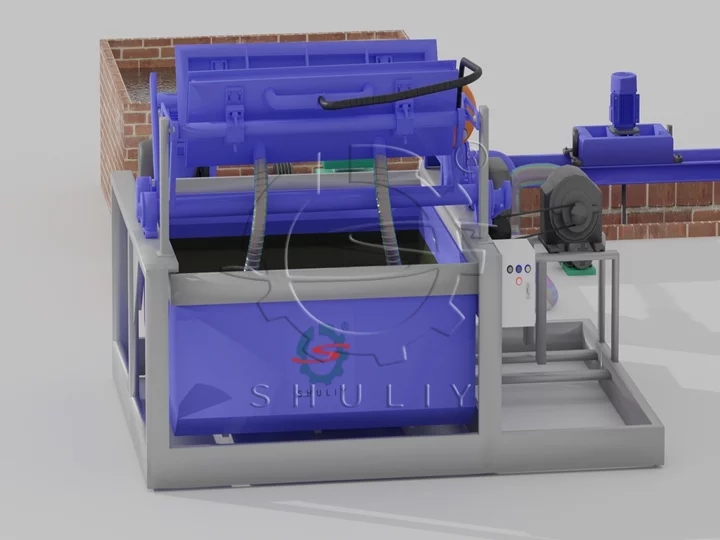

Egg Tray Production Line Machine

The egg tray production line machine encompasses a range of equipment crucial for efficient egg tray manufacturing. This includes paper pulper for waste paper, pulp molding machine, drying systems, and packaging machine, ensuring a seamless and eco-friendly production process. Our integrated solution guarantees high-quality output for egg tray manufacturers.

For egg tray manufacturers, it is important to analyze the investment cost. Besides, our professional will also help you get the profits in your business. And we provide all of equipment in egg tray manufacturing process.

Main Investment List for Egg Tray Manufacturers

| Investment item | How to estimate |

| Raw materials | One ton of waste paper can produce 12000-15000 egg trays. You will get the cost of per egg tray. |

| Labor | It takes from 4 to 6 people in this egg tray production line. For your local employment price, you can get the price. |

| Electricity | According to the output, it can be calculated according to the power, the higher the output, the lower the cost. |

| drying | Calculate the prices of electricity, coal, wood, natural gas, and diesel that need to be used for the output. |

| pigment | It is based on how many egg trays can be produced per kilogram. |

| purchase machine | Paper pulp, egg tray molding machine, egg tray dryer, packaging machine, and some supportive equipment. |

Cost Analysis for Egg Tray Manufacturers

Our comprehensive cost analysis for egg tray manufacturers covers various aspects, including raw materials, energy consumption, labor, and maintenance. Specific prices may vary based on factors such as country, region, and production volume. Drawing from our experience, larger machine outputs lead to lower cost per egg tray. For precise cost details, feel free to get in touch with us directly. Your successful egg tray manufacturing venture awaits.