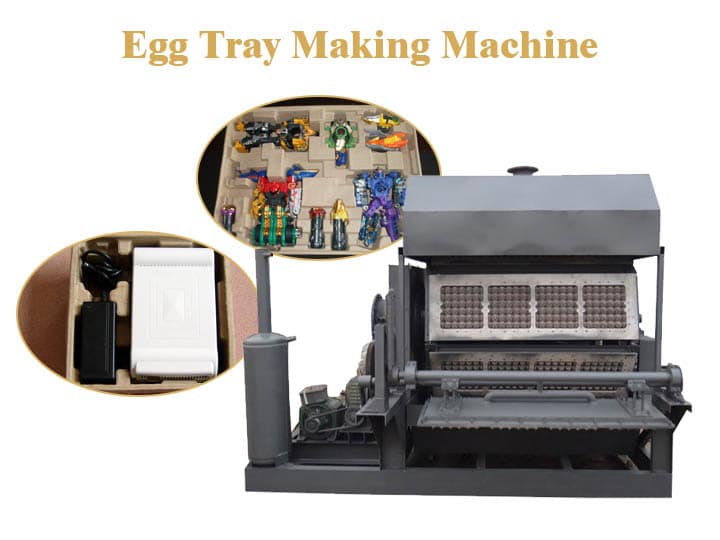

Nigeria again! — 4 side egg tray machine

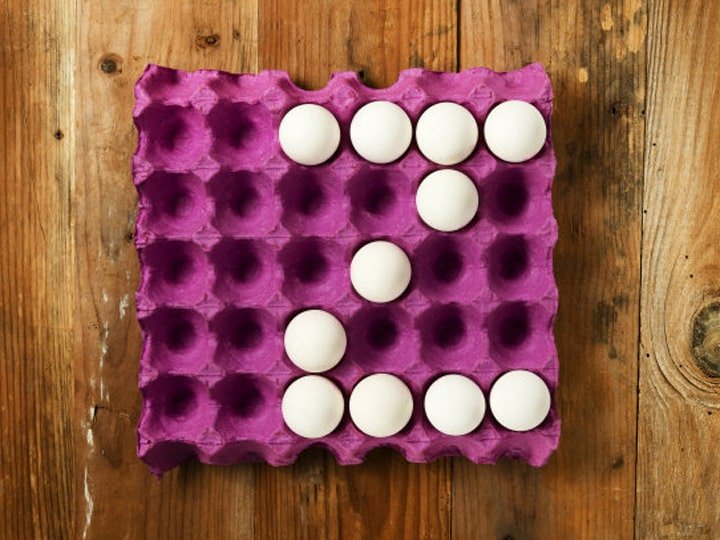

In June 2019, customers from Nigeria sent us an inquiry about the automatic egg tray machine. He said he owns a chicken farm and wants to carry eggs with egg trays for storage and transportation. He said that at the very beginning, his eggs were sold to some closer place, so the cost of egg support was not considered at the beginning. At present, the scale of chicken farms is expanding, and eggs can be sold everywhere. He began to buy egg trays from wholesalers. Gradually he found that making egg trays might be more cost-effective than buying them from wholesalers, so he sent us an inquiry to verify that his idea was correct.

Our sales consultant Tina has been selling automatic egg tray machines for two years. After understanding the customer’s needs, she listed the costs of making egg trays, such as labor costs, raw material costs, water fees, electricity and so on. Comparing the calculated production cost with the individual purchase price, Tina also elaborates on the generation of various costs to the customers. By comparison, the self-made egg saucer is not only cheaper in price, but also more reliable in quality.

He bought a beater and a four-sided egg tray making machine. At present, his egg tray can not only be used by himself but also sold to other farms. He has handed the egg tray production line to his younger brother and said that it is very likely that he will buy the egg tray machine again and use the production egg tray as his second investment project.

egg tray making by automatic egg tray making machine

electronic tray

wine tray

electronic tray

Why do customers choose to buy our fully automatic egg tray machine?

- Excellent quality and advanced technology. The outer layer of the automatic egg tray machine is painted with high-quality paint, which can effectively prevent rust and corrosion caused by contact with water for a long time. The egg tray machine adopts advanced German technology and has the characteristics of high production efficiency and low failure rate.

- Environmentally friendly. This machine uses waste paper as raw material, not only does it not produce harmful substances in the production process, but also can be recycled and used. It is a typical green, fashionable and environmentally friendly packaging today.

- It is widely used. It can be used for packaging eggs, fruits, wine, glass ceramics, small machinery, electronic components, etc. Not only has good protective and cushioning properties, but it also can improve the packaging grade.